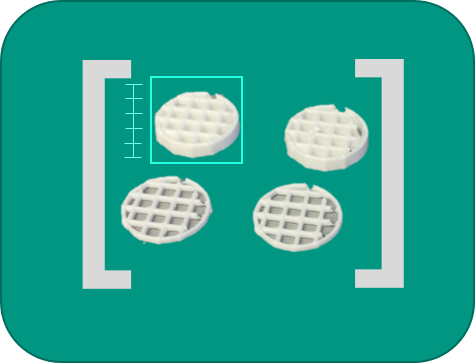

3D Printing and Process Analytical Technology (PAT)

For a safe use of Bioprinting in industrial settings the development of reliable and robust analytical methods is indispensable. To first understand and then control the printing process, it is important to investigate pre-printing phase, the actual printing process and the post-printing phase. A particular focus of our current research lies on analyzing the printing process by image-based methods. Via 2.5D and 3D image processing the printed objects are analyzed concerning their geometry and the exactness of print in comparison to the design. These methods can be used for the evaluation of the printability of different bioinks, for the estimation of the influence of manufacturing and process parameters as well as a promising tool for the printing process development.

Literature

Hydrogels and Scaffolds

Hydrogels are gel-like to solid materials which consist mainly of water. Their three-dimensional structure is maintained by the chemical or physical interactions of a polymer network. The applications of hydrogels are widely spread in biotechnology. They serve as a support structure (scaffold) for cellular growth in the field of tissue engineering and for the immobilization of enzymes in the field of biotransformation. The use of stimulus-responsive gels as sensors and the use of protein-based hydrogels as so-called soft materials are also currently the subject of research projects. All of these applications have in common, that novel materials must first be developed, characterized and optimized with regard to their processability for 3D printing.

Literature

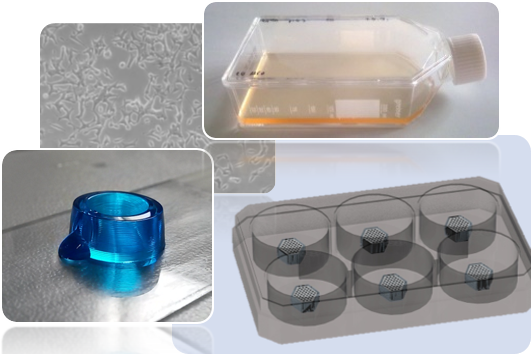

Bioprinting & Cell handling

Bioprinting is a method for the manufacturing of 3D tissue-like structures (scaffolds) currently used in pharmaceutical and medical research. In order to translate these artificial tissues form research towards industrial applications as well as medical use, key issues need to be solved including biological (e.g. vascularisation), material sciences and process development aspects. Our group is currently focusing on the process development part of cell handling in the field of bioprinting. Including the supply of the cell material, the introduction of this biological material in so-called bio inks and their processing. Furthermore, we are engaged in the establishment of suitable methods for cell characterization of printed structures